Imikhiqizo

-

Umshini Wokugcwalisa Amafutha Okupheka Ozenzakalelayo Ngokugcwele

Kufanelekela ukugcwaliswa: Amafutha adliwayo / Amafutha okupheka / Amafutha e-Sunflower / Izinhlobo zamafutha

Ububanzi Bebhodlela Lokugcwalisa: 50ml -1000ml 1L -5L 4L -20L

Umthamo uyatholakala: kusukela ku-1000BPH-6000BPH (okuyisisekelo ku-1L)

-

Imishini Yokwelapha Amanzi Ahlanzekile Yezimboni ze-RO

Kusukela ekuqaleni kwemishini yokungenisa amanzi evela emithonjeni yamanzi kuya ekupakisheni amanzi komkhiqizo, yonke imishini yokuhamba emanzini kanye namapayipi ayo kanye nama-valve epayipi afakwe isekethe yokujikeleza yokuhlanza i-CIP, engenza ukuhlanzwa okuphelele kwemishini ngayinye kanye nengxenye ngayinye yepayipi. Uhlelo lwe-CIP ngokwalo luhlangabezana nezidingo zezempilo, lungazijikelezisa ngokwalo, ukubulala amagciwane kuyalawuleka, futhi ukugeleza, izinga lokushisa, kanye nekhwalithi yamanzi eyingqayizivele yoketshezi olujikelezayo kungatholakala ku-inthanethi.

-

Hlanza uhlelo lwe-CIP oluzenzakalelayo endaweni yalo

Ukuhlanza endaweni (i-CIP) kuyisethi yezinqubo ezisetshenziselwa ukuhlanza kahle imishini yokucubungula ngaphandle kokususa amapayipi noma imishini.

Ukwakhiwa kwesistimu ngamathangi, ivalvu, iphampu, ukushintshanisa ukushisa, ukulawula umusi, ukulawula i-PLC.

Isakhiwo: 3-1 i-monoblock yokugeleza okuncane, ithangi elihlukile le-asidi/i-alkali/amanzi ngalinye.

Faka isicelo kabanzi embonini yokudla yobisi, ubhiya, iziphuzo njll.

-

Uhlelo lokulungiselela iziphuzo ezibandayo ezine-carbon

Isetshenziswa kabanzi kumaswidi, ekhemisi, ekudleni kobisi, epasta, eziphuzo, njll., ingasetshenziswa futhi endaweni yokudlela enkulu noma egumbini lokudlela ukubilisa isobho, ukupheka, isitshulu, ukubilisa i-congee, njll. iyithuluzi elihle lokucubungula ukudla ukuthuthukisa ikhwalithi, ukunciphisa isikhathi, nokuthuthukisa izimo zokusebenza.

-

Uhlelo lokuxuba nokulungisa ujusi

Isetshenziswa kabanzi kumaswidi, ekhemisi, ekudleni kobisi, epasta, eziphuzo, njll., ingasetshenziswa futhi endaweni yokudlela enkulu noma egumbini lokudlela ukubilisa isobho, ukupheka, isitshulu, ukubilisa i-congee, njll. iyithuluzi elihle lokucubungula ukudla ukuthuthukisa ikhwalithi, ukunciphisa isikhathi, nokuthuthukisa izimo zokusebenza.

Umsebenzi: ukulungiselela isiraphu.

-

I-Full Automatic PET Bottle Rotary Unscrambler

Lo mshini usetshenziselwa ukuhlunga amabhodlela e-polyester angahlelekile. Amabhodlela ahlakazekile athunyelwa endandatho yokugcina ibhodlela yebhodlela engaxhunywanga ngesiphakamisi. Ngokucindezela kwe-turntable, amabhodlela angena egumbini lebhodlela futhi azibeke wona. Ibhodlela lihlelwe ngendlela yokuthi umlomo webhodlela uqonde, futhi ukuphuma kwalo kuqhubekele enkambisweni elandelayo ngohlelo lokuhambisa amabhodlela oluqhutshwa umoya. Izinto zomzimba womshini zenziwe ngensimbi engagqwali esezingeni eliphezulu, kanti ezinye izingxenye zenziwe ngezinto zochungechunge ezingenabuthi nezihlala isikhathi eside. Ezinye izingxenye ezingenisiwe zikhethelwa izinhlelo zikagesi nezomoya. Yonke inqubo yokusebenza ilawulwa uhlelo lwe-PLC, ngakho-ke imishini inezinga eliphansi lokwehluleka kanye nokuthembeka okuphezulu.

-

Umhubhe Wokupholisa Ofudumeza Ibhodlela Ozenzakalelayo

Umshini wokufudumeza amabhodlela usebenzisa umklamo wokufudumeza osebenzisa umusi onezigaba ezintathu, izinga lokushisa lamanzi okufutha amanzi kufanele lilawulwe cishe kuma-degrees angu-40. Ngemva kokuba amabhodlela ephumile, izinga lokushisa lizoba cishe kuma-degrees angu-25. Abasebenzisi bangalungisa izinga lokushisa ngokwezidingo zabo. Konke ekugcineni kwesifudumeza, kufakwe umshini wokomisa ukuze uphefumule amanzi ngaphandle kwebhodlela.

Ifakwe uhlelo lokulawula izinga lokushisa. Abasebenzisi bangazilungisa ngokwabo izinga lokushisa.

-

I-Flat Conveyor Yebhodlela

Ngaphandle kwengalo yokusekela njll. eyenziwe ngepulasitiki noma ngezinto ze-rilsan, ezinye izingxenye zenziwe nge-SUS AISI304.

-

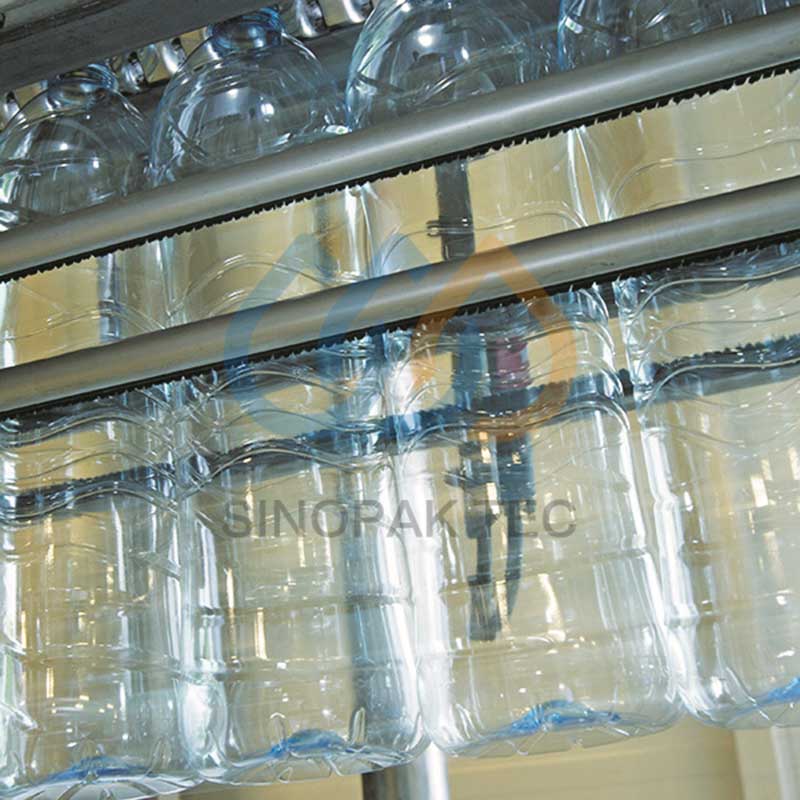

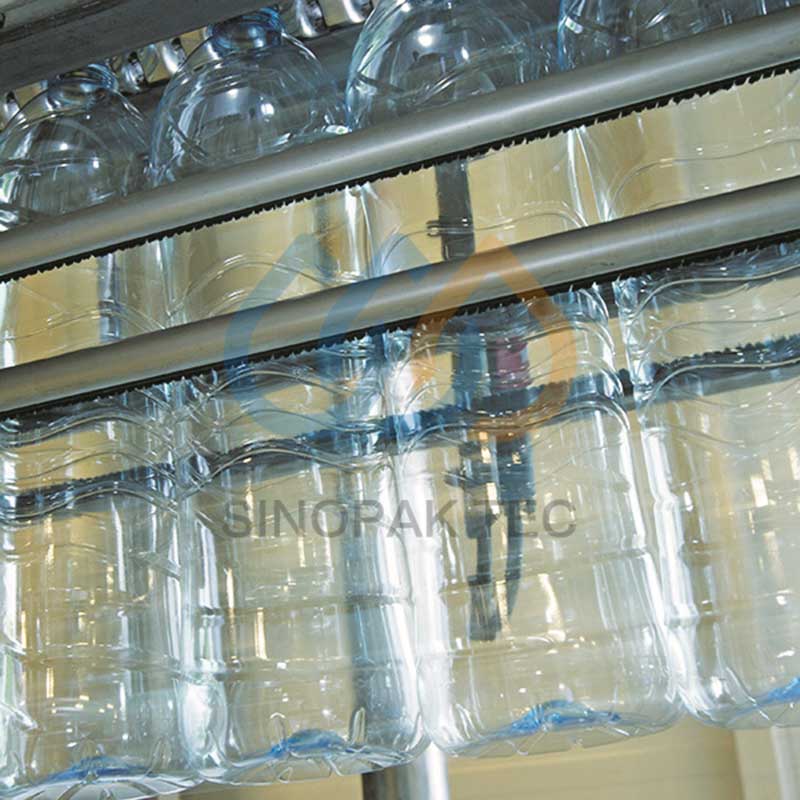

I-Air Conveyor Yebhodlela Elingenalutho

I-Air conveyor iyibhuloho eliphakathi kwe-unscrambler/blower kanye nomshini wokugcwalisa ongu-3 ku-1. I-Air conveyor isekelwa yingalo ephansi; i-air blower ibekwe ku-air conveyor. I-inlet ngayinye ye-air conveyor inesihlungi somoya ukuvimbela uthuli ukungena. Amasethi amabili eswishi ye-photoelectric abekwe ku-inlet yebhodlela ye-air conveyor. Ibhodlela lidluliselwa kumshini ongu-3 ku-1 ngomoya.

-

Okuphakelayo Okuzenzakalelayo kwe-Elevato Cap

Isetshenziselwa ngokukhethekile izivalo zamabhodlela eziphakanyisiwe ngakho-ke nikeza umshini we-capper usebenzisa. Isetshenziswa nomshini we-capper ndawonye, uma ushintsha ingxenye ethile ingasetshenziselwa nezinye izimpahla zehadiwe, umshini owodwa ungawusebenzisa kakhulu.

-

Umshini Wokuhlanza Amabhodlela Ophambene

Lo mshini usetshenziswa kakhulu ubuchwepheshe bokugcwalisa amabhodlela e-PET, lo mshini uzohlanza izivalo nomlomo webhodlela.

Ngemva kokugcwalisa nokuvala, amabhodlela azoguqulwa ngokuzenzakalelayo abe ngu-90°C ngalo mshini abe yi-flat, umlomo nezivalo kuzohlanzwa nge-internal thermal medium yayo. Isebenzisa uchungechunge lokungenisa oluzinzile futhi oluthembekile ngaphandle kokulimala kwebhodlela, isivinini sokudlulisela singashintshwa.

-

Amabhodlela eziphuzo zokudla Iphrinta yekhodi ye-laser

1. I-Fly desgin, eyenzelwe ngokukhethekile izixazululo zokubhala amakhodi ezimbonini.

2. Incane ngosayizi, engahlangabezana nendawo yokusebenza emincane.

3. Isivinini esisheshayo, Ukusebenza okuphezulu

5. Ukwamukela umthombo omuhle we-laser, ozinzile futhi othembekile.

6. Uhlelo lokusebenza lwesikrini sokuthinta esisodwa, kulula futhi kulula ukulusebenzisa.

7. Impendulo esheshayo ngemva kokuthengisa, ukuze usindise izinkathazo zakho futhi ukhuphule umkhiqizo.