100% Original Factory 5 Gallon Blow Molding Machine - Electrical Servo Type Drinking Water Bottle Blowing Molding Machine – SINOPAK

100% Original Factory 5 Gallon Blow Molding Machine - Electrical Servo Type Drinking Water Bottle Blowing Molding Machine – SINOPAK Detail:

1. Feeding system:

1)Continous and high speed preform feeding system.

2)No pneumatic claws were used, feeding faster, no air claws changing required, less part changing cost in future.

3) Multiple protection device for precise preform feeding.

2. Trasfer and heating system:

1) Horizontal rotation transfer style, no preform turnover, simple structure.

2) Compact preform-chain pitch design for efficient heating and reduce energy consumption.

3)Cooling channel applied in heating tunnel to guarantee no deform of preform neck.

4)Optimized ventilation to ensure heating consistency.

5) With function of preform temperature detection.

6)Easy access for heater maintenance and lamp changing.

3. Transfer and bottle out system:

1)Servo motor driven preform transfer system for quick transfer and precise preform locating.

2)No pneumatic clampers were used for bottle taking out, less maintenance in future, less running cost.

4. Stretching blowing and molding system:

1)Servo motor driven system with synchronized base blow mould for fast response operation.

2)Precision electromagnetic blowing valve group for fast and high productivity.

5. Control system:

1)Touch-panel control system for simple operation

2)Simens controlling system and servo motors, better system used.

3)9 inch LCD touch screen with 64K colors.

6. Clamping system:

No link rod,no toggle structure, simple and reliable servo clamping system. Less maintenance in future.

7. Others:

1)All electric mechanism to ensure high-speed operation and precise locating.

2)Design for quick mould change.

3)Less with high pressure recycle system, no separate low pressure input required.

4)Low energy consumption, low wear, more clean structure.

5)Easy directly connect to filling production line.

|

Model |

SPB-4000S |

SPB-6000S |

SPB-8000S |

SPB-10000S |

|

Cavity |

4 |

6 |

8 |

10 |

|

Output(BPH) 500ML |

6,000 pcs |

9,000 pcs |

12,000 pcs |

14000pcs |

|

Bottle size range |

Up to 1.5 L |

|||

|

Air consumption(m3/minute) |

6 cube |

8 cube |

10 cube |

12 |

|

Blowing pressure |

3.5-4.0Mpa |

|||

|

Dimensions (mm) |

3280×1750×2200 |

4000 x 2150 x 2500 |

5280×2150×2800 |

5690 x 2250 x 3200 |

|

Weight |

5000kg |

6500kg |

10000kg |

13000kg |

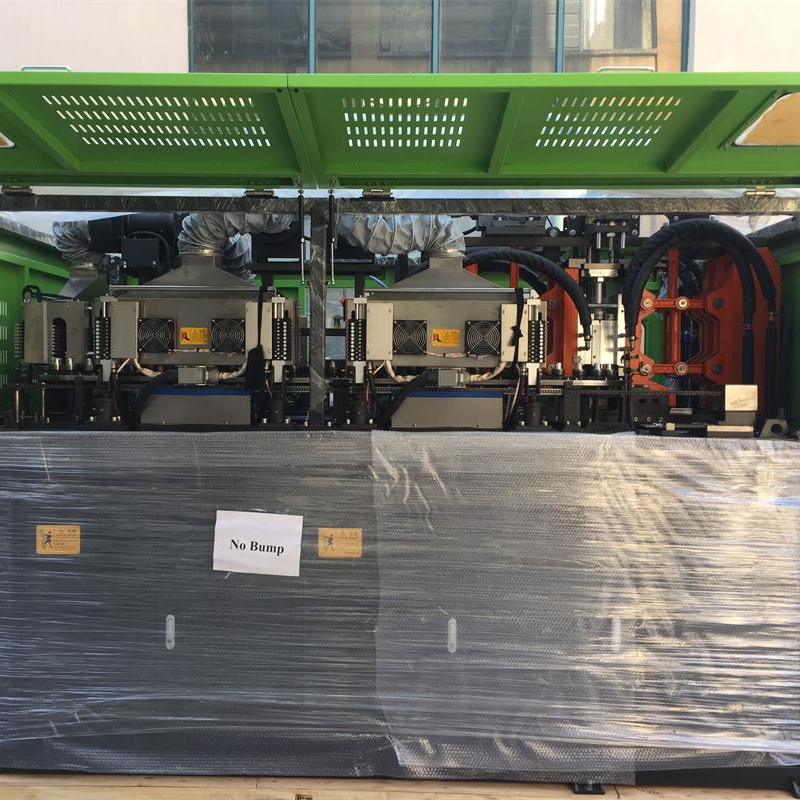

Product detail pictures:

Related Product Guide:

We insist about the theory of growth of 'High excellent, Performance, Sincerity and Down-to-earth working approach' to offer you with great company of processing for 100% Original Factory 5 Gallon Blow Molding Machine - Electrical Servo Type Drinking Water Bottle Blowing Molding Machine – SINOPAK , The product will supply to all over the world, such as: Suriname, Tunisia, South Africa, Make sure you genuinely feel free to send us your requirements and we are going to respond for you asap. We now have got a skilled engineering group to serve for your just about every detailed needs. Cost-free samples could be sent to suit your needs personally to understand much more information. In an effort to meet your requires, be sure to seriously feel free to make contact with us. You may send us emails and contact us directly. Moreover, we welcome visits to our factory from around the globe for much better recognizing of our organization. nd objects. In our trade with merchants of numerous countries, we usually adhere for the principle of equality and mutual benefit. It is really our hope to market, by joint efforts, each trade and friendship to our mutual advantage. We look forward to getting your inquiries.

We always believe that the details decides the company's product quality, in this respect, the company conform our requirements and the goods are meet our expectations.