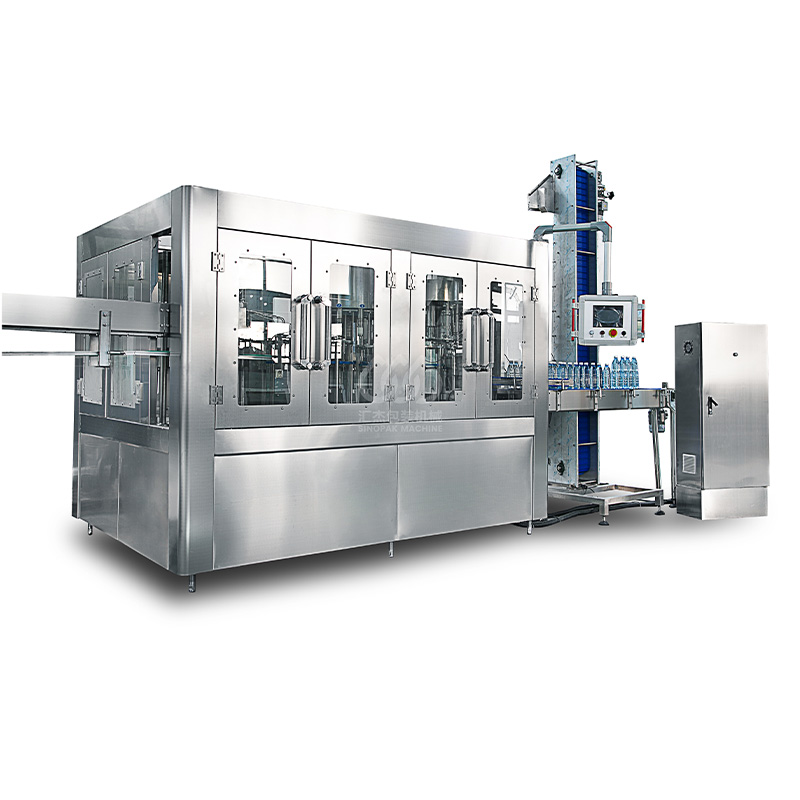

Factory Outlets Glass Bottling Line - Bottle Inverse Sterilize Machine – SINOPAK

Factory Outlets Glass Bottling Line - Bottle Inverse Sterilize Machine – SINOPAK Detail:

1. The machine is mainly composed of the local transmission chain system, a bottle body reversal chain system, rack, bottle flip guide, etc.

2. The machine automatically flips sterilization,self-reset, and the high temperature of the material in the bottle carrying out disinfection during the process, does not have to add any heat source, reaching energy-saving purposes.

3. The body of the machine uses SUS304 material, elegant and easy to use.

This machine is a necessary machinery for juice, tea and other hot filling beverage production line.

| Model | Production capacity(b/h) | Bottle reversing time(s) | Belt speed(m/min) | Power(kw) |

| DP-8 | 3000-8000 | 15-20s | 4-20 | 3.8 |

| DP-12 | 8000-15000 | 15-20s | 4-20 | 5.6 |

Product detail pictures:

Related Product Guide:

Control the standard by the details, show the power by quality. Our business has strived to establish a highly efficient and stable team staff and explored an effective good quality regulate course of action for Factory Outlets Glass Bottling Line - Bottle Inverse Sterilize Machine – SINOPAK , The product will supply to all over the world, such as: Greek, Salt Lake City, Philadelphia, All the imported machines effectively control and guarantee the machining precision for the products. Besides, we have a group of high-quality management personnels and professionals, who make the high-quality products and have the ability to develop new products to expand our market home and abroad. We sincerely expect customers come for a blooming business for both of us.

The company can keep up with the changes in this industry market, product updates fast and the price is cheap, this is our second cooperation, it's good.

Write your message here and send it to us