Leading Manufacturer for 4 Cavity Blow Moulding Machine - Full-automatic Blow Molding Machine – SINOPAK

Leading Manufacturer for 4 Cavity Blow Moulding Machine - Full-automatic Blow Molding Machine – SINOPAK Detail:

Equipment Feature:

Controller system

PLC, full-automatic working

Touch screen, easy operate. Each of error operates will automatic display and alarm.

Lack of pet perform, it will be alarm, and then stop to work in automatic.

Each of the heater have independence temperature controller.

Preform Feeder

The preform stocked in the hopper are transported by conveyor and are sorted neck upwards for the feed ramp in to the perform oven automatically, the performs are now read to enter the oven equipped with its infra-lamps.

Linear transport oven

The heating of the performs is optimized by the new modular oven with 6 layers of heating lamps. It guarantees the ideal temperature for quality blowing.

The preforms self rotated by high quality heat resistant and wear-resistant silica gel during the continuous movement.

Due to the small gaps between the preforms, it requires less electric costs. So it can save the electronic. It is economic running.

Each lamp’s horizontal position is adjustable to keep the machine flexible.

Clamp Unit

The clamp unit is the key to guarantee the flexibility and steady work. We adopt double cylinder, so it is steadier.

Sensor system

Adopts high quality imported sensor & switch system including proximity switch, photoelectric switch, and electronic magnet switch to keep production process going step by step and avoid any possible damage on machine.

Air Recovery system

| Model | SPB-2000 | SPB-4000 | SPB-6000 | SPB-8000 |

| Cavity | 2 | 4 | 6 | 8 |

| Output(BPH) 500ML | 2,000 pcs | 4,000 pcs | 6,000 pcs | 8000pcs |

| Bottle size range | Up to 1.5 L | |||

| Air consumption(m3/minute) | 2 cube | 4cube | 6cube | 8 cube |

| Blowing pressure |

3.5-4.0Mpa |

|||

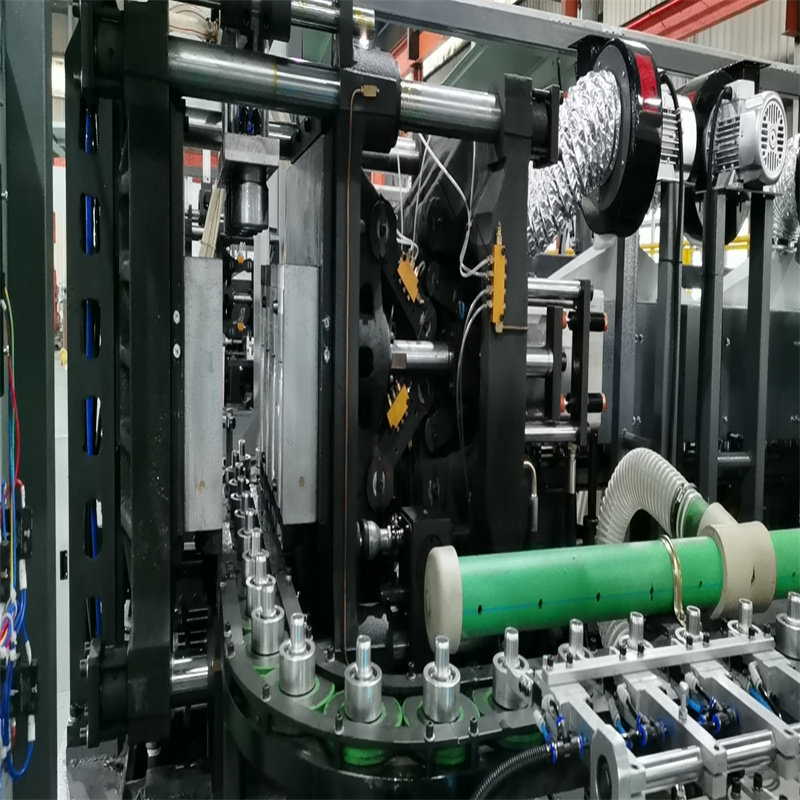

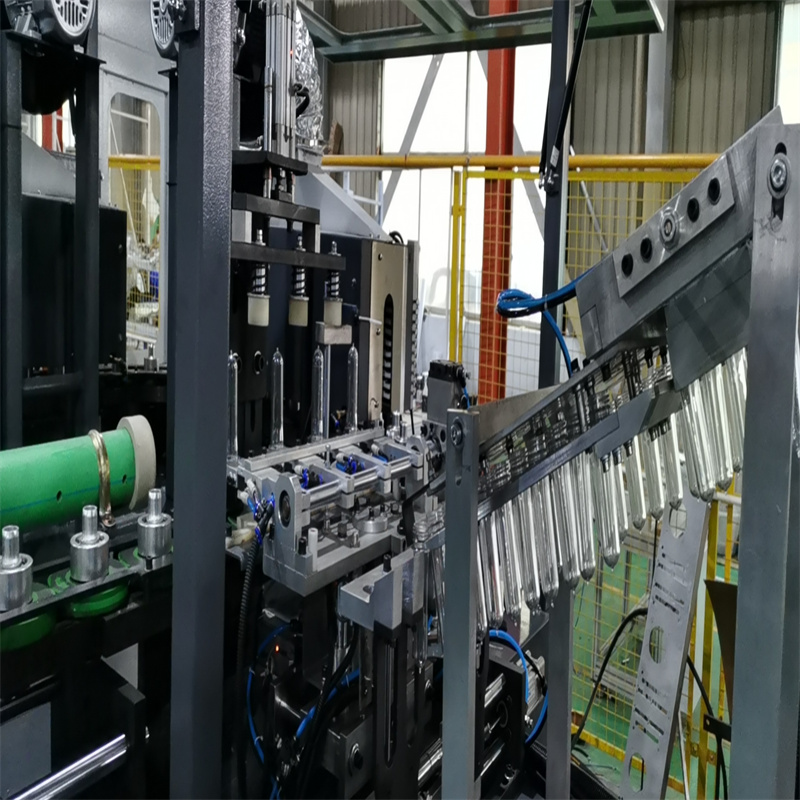

Product detail pictures:

Related Product Guide:

We've been committed to offering easy,time-saving and money-saving one-stop purchasing support of consumer for Leading Manufacturer for 4 Cavity Blow Moulding Machine - Full-automatic Blow Molding Machine – SINOPAK , The product will supply to all over the world, such as: Slovakia, Jeddah, Croatia, We've been persisting in the business essence Quality First, Honoring Contracts and Standing by Reputations, providing customers with satisfying products and service. Friends both at home and abroad are warmly welcome to establish everlasting business relations with us.

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.